COMPONENTS

The components that are required to us by our customers, represent often the base for the assembly of high quality finished products. Frequently the company we work with have no time and specific tooling to produce some essential parts for the sake of success of their products.

At this stage comes Intermobel into play, providing the know-how and the specific equipments to supply even just one single piece.

We can manufacture metal components ready to be used in the most diverse products. We produce, even under an exclusive contract, for the following sectors:

● Indoor and outdoor furniture

● Automotive

● Heating and industrial plant building

● Equipments for the disabled

● Lighting

For a budget estimate or a project feasibility assessment, we encourage you to contact us directly.

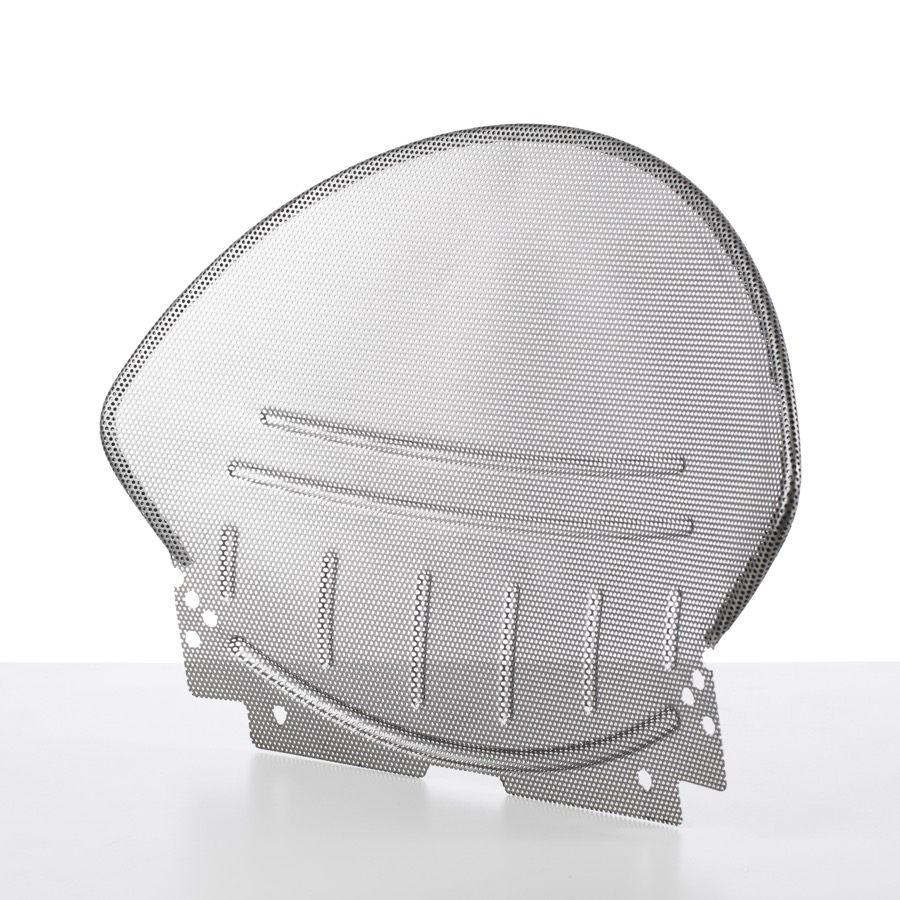

Backrest in perforated sheet

Projecting and manufacturing in perforated steel of a seat already designed and distributed in wood and plastic.

Produced as per our customer’s requirement to supply a seat also in areas where it was not possible to place materials other than metal for its durability and fire-resistance.

To produce a non-deformable seat in perforated sheet: an operation that may look impossible, but at the end patience and expertise led to the realisation of a product distributed worldwide.

Seat in pressed sheet

Seat in pressed sheet of important dimension.

Moulds and tooling are created in our technical unit staffed by highly talented and experienced people.

Chair Base BRN

Base in steel with four spokes for an upholstered armchair.

Made on customer’s request in drawn flat steel.

As for every item produced with this type of material, the perfect neatess of the weldings and the glossiness of the metal are essential for the success of the product.

Side frame in aluminium profile

It’s an aluminium profile with a very peculiar hollow section bent to variable radius and with further processes of CNC milling and drillig.

It’s side frame for office chairs with mesh seat.

The aluminium profile is specially tailored for this product, it has a side groove designed to contain a tie steel rod. It’s importat that the groove is not deformed by the production processes otherwise the assembly can’t be performed.

Steel shaped leg

These legs in steel were born from our customer’s desire to place a chair, previously designed with wooden legs, also in public areas where higher features of strenght and durabilty are requiered.

Leg in aluminium profile

The leg for the 18000 Chair, is manufactured with an aluminium tube with an oval section.

The peculiarity of this original process is the transformation of the tube that is formed until it takes the round shape where the flex mechanism has to be plugged in.

Back support for chairs with Pivot motion

It’s the key-component of the chairs Grazie and Strive manufactured for KI and designed by Giancarlo Piretti.

The particularity of these back supports for the chairs Grazie and Strive is the Pivot motion that follow the natural body movements of tilting and rotation while sitting, ensuring in this way a constant lumbar support and a pleasant relax sensation.

Ideal as an operative chair as well as for conference rooms.

Back support for chairs with Pivot motion

It’s the key-component of the chairs Grazie and Strive manufactured for KI and designed by Giancarlo Piretti.

The particularity of these back supports for the chairs Grazie and Strive is the Pivot motion that follow the natural body movements of tilting and rotation while sitting, ensuring in this way a constant lumbar support and a pleasant relax sensation.

Ideal as an operative chair as well as for conference rooms.